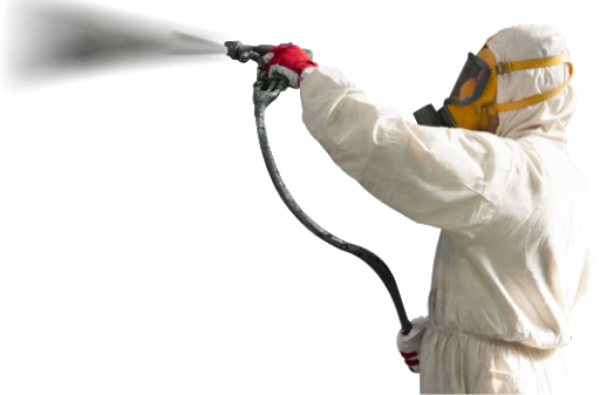

Blasting is an effective and efficient way of pretreating different surfaces.

Through blasting, impurities such as rust, older paint layers and other contaminants are removed.

The cleaning process ensures that a primer can adhere better to the surface. This causes the final layers of paint or coating to adhere better, which results in a better end product.

We use different methods for blasting. For example, we can use:

- corundum blasting

- and dry ice blasting